News

- Coconut shell charcoal machine priceDiscover the latest Coconut Shell Charcoal machine prices and secure the best deals on quality equipment. Outline / What is this content about: Introduction to the significance of Coconut Shell Charcoal machines. Explaining the factors influencing machine prices. List and describe top suppliers of Coconut Shell Charcoal machines. Compare prices and features of different machine models. Tips for finding the best deals and discounts. Case studies of successful machine investments. Maintenance and cost-saving considerations. Customer reviews and testimonials. Future trends in Coconut Shell Charcoal machine pricing. Conclusion summarizing key takeaways for buyers. What keywords and topics are recommended or required: Coconut Shell Charcoal Machine Prices Charcoal Machine Cost Best Deals on Charcoal Machines Coconut Shell Charcoal Equipment Coconut Charcoal Machine Models Charcoal Machine Suppliers Discounted Charcoal Machines Charcoal Machine Investment Maintenance of Charcoal Equipment Trends in Charcoal Machine Pricing What key questions do readers have that need to be answered: What are the current Coconut Shell Charcoal machine prices? What factors influence the cost of these machines? Can I find affordable and high-quality charcoal machines? How do different machine models compare in terms of price and features? Are there any tips for securing the best deals and discounts? Are there successful case studies of businesses investing in charcoal machines? What maintenance considerations can help reduce machine costs? Are there customer reviews or testimonials for these machines? What are the future trends in Coconut Shell Charcoal machine pricing? What should buyers take away when considering these machine prices?

2023 09/18

- Discover the advantages of carbonization machines in achieving high-quality charcoal productionExplore the benefits of using carbonization machines for superior charcoal production. Outline / What is this content about: Introduction to Carbonization Machines Definition and purpose Significance in the charcoal production process The Importance of High-Quality Charcoal Understanding the demand for quality Applications in various industries How Carbonization Machines Work Explaining the carbonization process Role in producing high-quality charcoal Different types of carbonization machines Advantages of Using Carbonization Machines High-quality charcoal production Increased efficiency and productivity Environmental benefits Cost-effectiveness Real-World Examples: Success Stories of Carbonization Machine Users Case studies showcasing businesses benefiting from these machines Choosing the Right Carbonization Machine Factors to consider when selecting a machine Capacity, sustainability features, and fuel sources Maintenance and Troubleshooting Essential maintenance practices Common issues and solutions The Future of Carbonization Machines Technological advancements in carbonization Sustainability trends in the industry Conclusion: Embracing Carbonization Machines for Quality Charcoal Production Summarizing the benefits and potential of these machines What keywords and topics are recommended or required: Carbonization machines High-quality charcoal production Carbonization process Benefits of carbonization machines Efficiency in charcoal production Environmental impact Case studies of carbonization machine users Choosing the right carbonization machine Maintenance of carbonization machines Future of carbonization technology What key questions do readers have that need to be answered: How do carbonization machines contribute to high-quality charcoal production? Why is high-quality charcoal important, and what are its applications? Can you explain the carbonization process and its role in charcoal production? What specific advantages come with using carbonization machines? Are there real-world examples of businesses benefiting from these machines? What factors should I consider when choosing a carbonization machine? How can I ensure proper maintenance and troubleshoot common issues with carbonization machines? What innovations are expected in carbonization technology? How do carbonization machines contribute to environmental sustainability in charcoal production? How can I maximize efficiency and productivity using carbonization machines in charcoal production?

2023 09/06

- Coconut shell charcoal suppliersDiscover the leading Coconut Shell Charcoal suppliers worldwide. Find high-quality sources for your charcoal needs. Outline / What is this content about: Introduction to the importance of Coconut Shell Charcoal suppliers. Highlight the criteria for selecting top suppliers. List and describe the top global Coconut Shell Charcoal suppliers. Showcase their specialties and product range. Discuss the sustainability practices of these suppliers. Provide insights into pricing and delivery options. Customer reviews and testimonials. Tips for making the right choice among these suppliers. Case studies of successful partnerships. Conclusion summarizing the key takeaways. What keywords and topics are recommended or required: Coconut Shell Charcoal Manufacturers Best Charcoal Suppliers Global Charcoal Supply Sustainable Charcoal Sourcing Charcoal Supplier Reviews Coconut Shell Charcoal Pricing Charcoal Delivery Options Quality Charcoal Products Choosing Charcoal Suppliers Charcoal Supplier Partnerships What key questions do readers have that need to be answered: Who are the top Coconut Shell Charcoal suppliers worldwide? How do I select the best supplier for my charcoal needs? What products and specialties do these suppliers offer? Are these suppliers committed to sustainable practices? What are the pricing and delivery options available? Are there any customer reviews or testimonials? Do you have tips for choosing the right charcoal supplier? Can you provide examples of successful supplier partnerships? Are there any case studies showcasing supplier reliability? What are the key takeaways when considering these suppliers?

2023 08/23

- Buy the Best Coal Processing MachineDiscover how to purchase the ideal coal processing machine for your needs. Make an informed decision and optimize your coal production process. Outline / What is this content about: Introduction Brief overview of the importance of coal processing machines. Understanding Coal Processing Machines Explanation of what coal processing machines are and their significance in coal production. Factors to Consider When Buying a Coal Processing Machine Discuss key factors that buyers should take into account before making a purchase. Types of Coal Processing Machines Explore various types of machines available in the market for coal processing. Top Brands and Models Highlight reputable brands and models known for quality coal processing machines. Where to Buy Provide insights into where readers can find and purchase the best coal processing machines. Price Range and Budgeting Discuss the price range of coal processing machines and offer budgeting tips. Maintenance and Care Guide on how to maintain and care for a coal processing machine to ensure longevity. Customer Reviews and Recommendations Showcase real customer experiences and recommendations for specific machines. Conclusion Summarize key takeaways and encourage readers to make an informed purchase decision. What keywords and topics are recommended or required: Coal processing machine Coal production equipment Choosing the right machine Types of coal processing machines Top brands in coal processing Where to buy coal processing machines Budgeting for a coal processing machine Maintenance tips Customer reviews Informed purchase decision What key questions do readers have that need to be answered: How do coal processing machines work? What factors should I consider when buying a coal processing machine? Are there different types of coal processing machines available? Which brands are known for quality coal processing machines? Where can I purchase coal processing machines? What is the price range for these machines, and how can I budget for one? How do I ensure the longevity of my coal processing machine? Can I find customer reviews and recommendations for specific machines? What are the benefits of investing in a high-quality coal processing machine? How can I make an informed decision when buying a coal processing machine?

2023 08/02

- Charcoal machine maintenanceExplore the essential tips and techniques for effective charcoal machine maintenance. Outline / What is this content about: Introduction to Charcoal Making Machines Brief overview of their importance in charcoal production. Why Maintenance Matters Emphasizing the significance of regular maintenance. Types of Charcoal Making Machines An overview of the different types available in the market. Maintenance Schedule Creating a maintenance timetable for optimal performance. Cleaning and Lubrication Detailed steps for cleaning and lubricating machine components. Inspecting and Replacing Parts How to identify worn-out or damaged parts and replace them. Safety Measures Ensuring safe maintenance practices for operators. Troubleshooting Common Issues Addressing common problems and their solutions. Extending Machine Lifespan Tips for prolonging the life of your charcoal making machine. Environmental Considerations Discussing eco-friendly maintenance practices. Cost-Effective Maintenance Strategies to maintain machines without breaking the bank. Case Studies: Success Stories of Effective Maintenance Real-world examples of businesses benefiting from proper maintenance. Conclusion: The Key to Consistent Performance Summarizing the importance of maintenance in charcoal production. What keywords and topics are recommended or required: Charcoal machine maintenance Maintaining charcoal making machines Charcoal machine cleaning Machine maintenance schedule Charcoal machine lubrication Replacing machine parts Troubleshooting machine issues Extending machine lifespan Eco-friendly maintenance Cost-effective machine maintenance What key questions do readers have that need to be answered: Why is maintenance crucial for charcoal making machines? What are the different types of charcoal making machines available? How do I create a maintenance schedule for my machine? What are the proper cleaning and lubrication procedures for these machines? How can I identify and replace worn-out machine parts? What safety measures should I follow during machine maintenance? What are some common issues with charcoal making machines and how can I troubleshoot them? What tips can help me extend the lifespan of my charcoal machine? Are there environmentally friendly ways to maintain these machines? How can I effectively maintain my machine without incurring high costs?

2023 07/26

- Coconut Shell Charcoal MachinesExplore the impact of Coconut Shell Charcoal Machines on the charcoal industry and discover their transformative capabilities. Outline / What is this content about: Introduction to Coconut Shell Charcoal Machines The Significance of Coconut Shell Charcoal How Coconut Shell Charcoal Machines WorkCarbonization Process Briquette Formation Efficiency and Automation Benefits of Using Coconut Shell Charcoal MachinesSustainable Sourcing High-Quality Charcoal Production Cost-effectiveness Case Studies: Success Stories of Businesses Utilizing Coconut Shell Charcoal Machines Applications of Coconut Shell CharcoalCooking and Barbecues Industrial and Agricultural Use Environmental Benefits Considerations for Choosing the Right Coconut Shell Charcoal MachineCapacity and Output Environmental Impact Fuel Source Maintenance and TroubleshootingRegular Maintenance Practices Common Issues and Solutions The Future of Coconut Shell Charcoal MachinesTechnological Advancements Sustainability Trends Conclusion: Embracing Coconut Shell Charcoal Machines for a Sustainable Charcoal Industry What keywords and topics are recommended or required: Coconut Shell Charcoal Machines Coconut shell charcoal production Carbonization process Briquette formation Benefits of coconut shell charcoal Sustainable charcoal sourcing Case studies of coconut shell charcoal use Applications of coconut shell charcoal Choosing the right charcoal machine Maintenance of coconut shell charcoal machines What key questions do readers have that need to be answered: What are Coconut Shell Charcoal Machines, and why are they important? How does coconut shell charcoal contribute to the charcoal industry? Can you explain the working process of Coconut Shell Charcoal Machines? What advantages do these machines offer for sustainable charcoal production? Are there real-world examples of businesses benefiting from Coconut Shell Charcoal Machines?

2023 07/05

- Explore the world of charcoal making machines and learn how they can revolutionize your productionExplore the world of charcoal making machines and learn how they can revolutionize your production Discover the capabilities of charcoal making machines and their potential to transform your production processes. Outline / What is this content about: Introduction to Charcoal Making Machines The Significance of Charcoal in Various Industries Types of Charcoal Making MachinesBiomass Charcoal Machines Sawdust Charcoal Machines Coconut Shell Charcoal Machines Charcoal Briquette Machines How Charcoal Making Machines WorkCarbonization Process Briquette Formation Automation and Efficiency Benefits of Using Charcoal Making MachinesIncreased Production Improved Quality Cost-effectiveness Sustainability Case Studies: Success Stories of Businesses Using Charcoal Making Machines Considerations for Choosing the Right MachineCapacity and Output Fuel Source Environmental Impact Maintenance and TroubleshootingRegular Maintenance Practices Common Issues and Solutions Exploring Future Innovations in Charcoal Making Conclusion: Embracing Charcoal Making Machines for Enhanced Production What keywords and topics are recommended or required: Charcoal making machines Charcoal production equipment Biomass charcoal machines Sawdust charcoal machines Coconut shell charcoal machines Charcoal briquette machines Benefits of charcoal making machines Charcoal machine maintenance Sustainability in charcoal production Future innovations in charcoal making What key questions do readers have that need to be answered: What are charcoal making machines, and why are they important? How does charcoal play a role in various industries? What are the different types of charcoal making machines available? Can you explain the working process of charcoal making machines? What benefits can businesses gain from using charcoal making machines? Are there real-world examples of successful businesses using these machines? What factors should I consider when choosing the right charcoal making machine? How can I maintain and troubleshoot charcoal

2023 06/28

- Innovations in Charcoal MachinesExplore the latest breakthroughs and advancements in charcoal machine innovations, revolutionizing the charcoal production industry. Outline / What is this content about: Introduction to Charcoal Machines The Evolution of Charcoal Production Technological Advancements in Charcoal Machines Automation and efficiency Enhanced quality control Sustainable production methods Innovative Features in Modern Charcoal Machines Smart sensors and monitoring Energy-efficient designs Integration of IoT (Internet of Things) Impact on Charcoal Production Increased productivity Higher-quality charcoal Cost reduction and sustainability Case Studies: Successful Implementation of Innovations Future Trends in Charcoal Machine Innovations Predictive maintenance AI and machine learning applications Environmental considerations How to Adopt and Stay Updated Choosing the right innovations for your business Resources for staying informed Benefits and Challenges Pros and cons of adopting innovations Overcoming implementation challenges Conclusion: Embracing the Future of Charcoal Production What keywords and topics are recommended or required: Charcoal machine innovations Innovations in charcoal production Technological advancements in charcoal machines Modern charcoal machine features Impact of innovations on charcoal production Case studies of innovation implementation Future trends in charcoal machine innovations Adopting innovations in charcoal production Benefits of innovation in charcoal machines Challenges in implementing charcoal machine innovations What key questions do readers have that need to be answered: What are the latest innovations in charcoal machines? How have charcoal production techniques evolved over time? What technological advancements are enhancing charcoal machines? What innovative features can I find in modern charcoal machines? What benefits do these innovations bring to charcoal production? Are there real-world examples of businesses successfully implementing innovations? What future trends can we expect in charcoal machine innovations? How can I choose and adopt the right innovations for my charcoal production? What are the advantages and disadvantages of incorporating these innovations? What challenges might I face when implementing innovative charcoal machines?

2023 06/05

- Trends in the Charcoal Production IndustryExplore the must-have equipment for efficient charcoal production. Discover the key to high-quality charcoal. Outline / What is this content about: Introduction to Charcoal Production Equipment Types of Charcoal Production Gear Charcoal Kilns Carbonization Machines Briquette Machines Extruder Machines Grinding and Crushing Equipment Benefits of Using Quality Equipment Increased Efficiency Improved Charcoal Quality Cost Savings Sustainability Maintenance and Troubleshooting Regular Maintenance Practices Common Issues and Solutions Where to Find Reliable Equipment Suppliers and Brands Customer Reviews Considerations for Purchasing Local Services and Rentals Repair and Maintenance Services Rental Options DIY Charcoal Production Gear Homemade Machine Plans Building Components Safety Measures in Charcoal Production Operating Guidelines Ventilation and Fire Safety Conclusion and Future of Charcoal Production Equipment What keywords and topics are recommended or required: Charcoal production equipment Essential charcoal gear Charcoal kilns Carbonization machines Briquette machines Extruder machines Charcoal equipment benefits Charcoal equipment maintenance Reliable equipment suppliers DIY charcoal production What key questions do readers have that need to be answered: What equipment is essential for charcoal production? How do different types of equipment affect the quality of charcoal? What are the benefits of investing in quality charcoal production gear? How can I maintain and troubleshoot charcoal production equipment? Where can I find reliable suppliers and brands for charcoal equipment? Are there local services or rental options for equipment?

2023 06/01

- Essential Charcoal Production GearExplore the must-have equipment for efficient charcoal production. Discover the key to high-quality charcoal. Outline / What is this content about: Introduction to Charcoal Production Equipment Types of Charcoal Production Gear Charcoal Kilns Carbonization Machines Briquette Machines Extruder Machines Grinding and Crushing Equipment Benefits of Using Quality Equipment Increased Efficiency Improved Charcoal Quality Cost Savings Sustainability Maintenance and Troubleshooting Regular Maintenance Practices Common Issues and Solutions Where to Find Reliable Equipment Suppliers and Brands Customer Reviews Considerations for Purchasing Local Services and Rentals Repair and Maintenance Services Rental Options DIY Charcoal Production Gear Homemade Machine Plans Building Components Safety Measures in Charcoal Production Operating Guidelines Ventilation and Fire Safety Conclusion and Future of Charcoal Production Equipment What keywords and topics are recommended or required: Charcoal production equipment Essential charcoal gear Charcoal kilns Carbonization machines Briquette machines Extruder machines Charcoal equipment benefits Charcoal equipment maintenance Reliable equipment suppliers DIY charcoal production What key questions do readers have that need to be answered: What equipment is essential for charcoal production? How do different types of equipment affect the quality of charcoal? What are the benefits of investing in quality charcoal production gear? How can I maintain and troubleshoot charcoal production equipment? Where can I find reliable suppliers and brands for charcoal equipment? Are there local services or rental options for equipment? Can I build my charcoal production gear with DIY plans? What safety measures should be followed when using this equipment? How can I improve the efficiency of my charcoal production? What does the future hold for charcoal production equipment?

2023 05/19

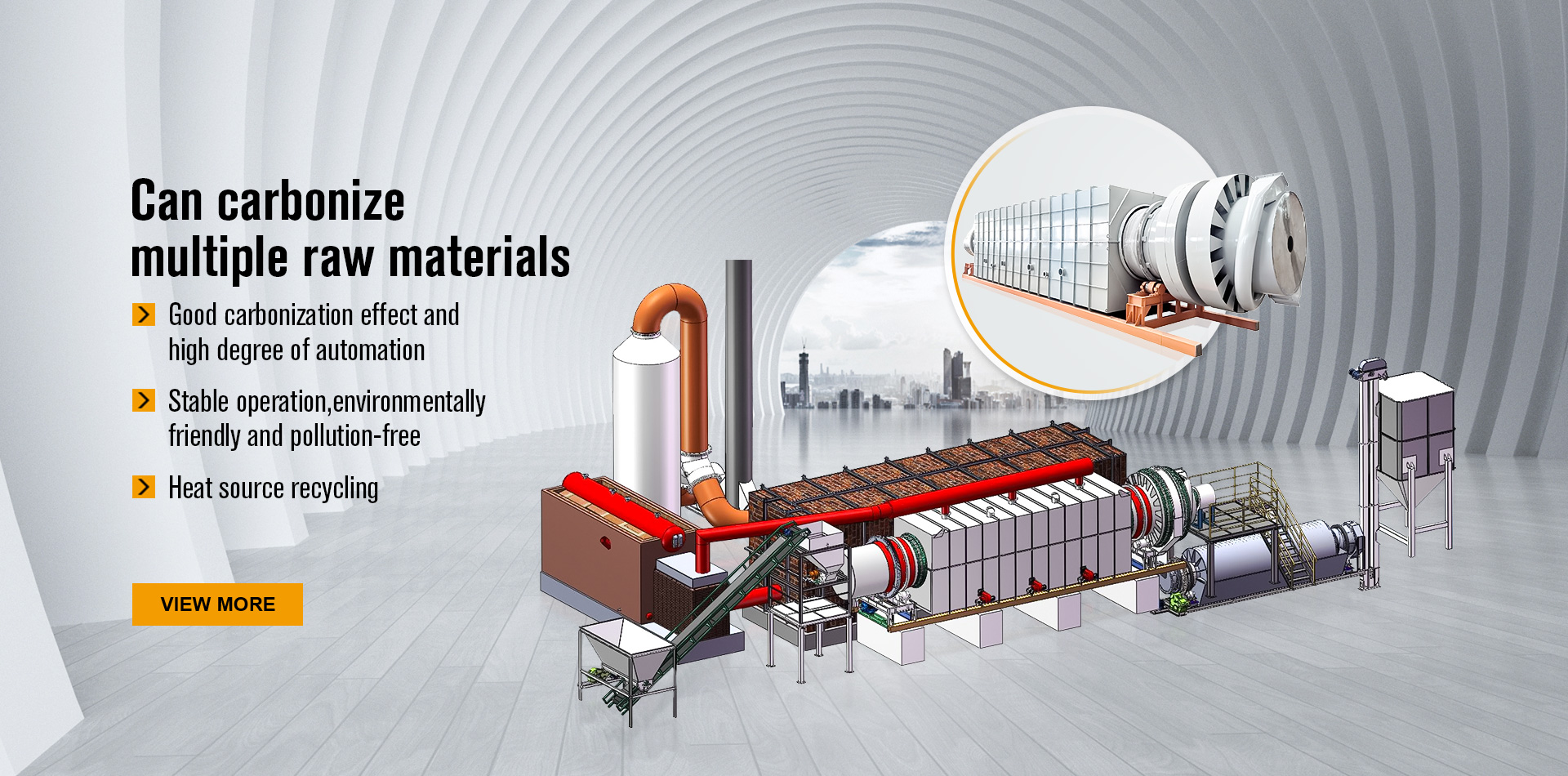

- Biomass Carbonization ProcessCarbonization is one of the important processes in the production of activated carbon. It usually includes two parts: raw material carbonization and exhaust gas treatment. Raw material carbonization is mainly carried out in a carbonization furnace. After the material enters the feed bin through the feeding port, it is fed into the carbonization furnace by the screw feeder. Depending on the inclination and rotation of the furnace body, the material moves slowly from the feeding port to the discharging port, gradually passing through the drying zone, the pyrolysis zone, and the carbonization zone. In this process, the carbonization furnace heats the material through thermal radiation so that the material is decomposed at high temperature to discharge non-carbon substances such as oxygen and hydrogen, and form fixed carbon with a skeleton structure and a certain strength to the greatest extent. The tail gas produced in the carbonization process is mainly composed of two parts: the high-temperature gas produced by fuel combustion and the volatile gas produced by the material thermal decomposition. They all contain a small number of harmful substances, which will cause certain pollution, so they need to be treated before they can be directly discharged into the atmosphere. Under normal circumstances, the tail gas will be sent into an incinerator, fully combusted at a high temperature of 900-1100 ℃ until all combustible gases and harmful substances are burned into CO2, and then discharged into the atmosphere.

2023 05/04

- Raw Materials For Activated Carbon ProductionThere are many kinds of raw materials for the activated carbon production, and almost all carbon-containing materials can be used as raw materials, such as wood, sawdust, coal, walnut shell, fruit stone, coconut shell, oil palm, bamboo, palm kernel, petroleum coke, and so on. Coconut and walnut shells are generally considered the best materials. Activated carbons from them have high strength and very fine pores. Most of these raw materials are cheap and easy to obtain, coupled with the simple production process and a broad market, in general, activated carbon production is a novice-friendly and promising investment direction! Double-layer design makes the lower part of Beston charcoal production plant contact the hot air as much as possible, this design is helpful to raise the heat utilization efficiency from the beginning. The lower layer equipments utilize residue heat in carbonizing gas to flash steam the materials. This is the second stage to raise the utilization efficiency of heat. The optimized and concentration multi-pipe design of hot exhaust gas (generated from gasifier or hot blast heater) recycling pipe, carbonizing and fission heat collecting pipe, flash steaming steam collecting pipe, combustion emission collecting pipe can raise the heat utilization efficiency in the third time. After three time of optimized usage of heat, the temperature of the emission gas is below 100 centigrade. Under the inspection of related institutes, the heat use ratio of our charcoal equipment is over 85%.

2023 05/03

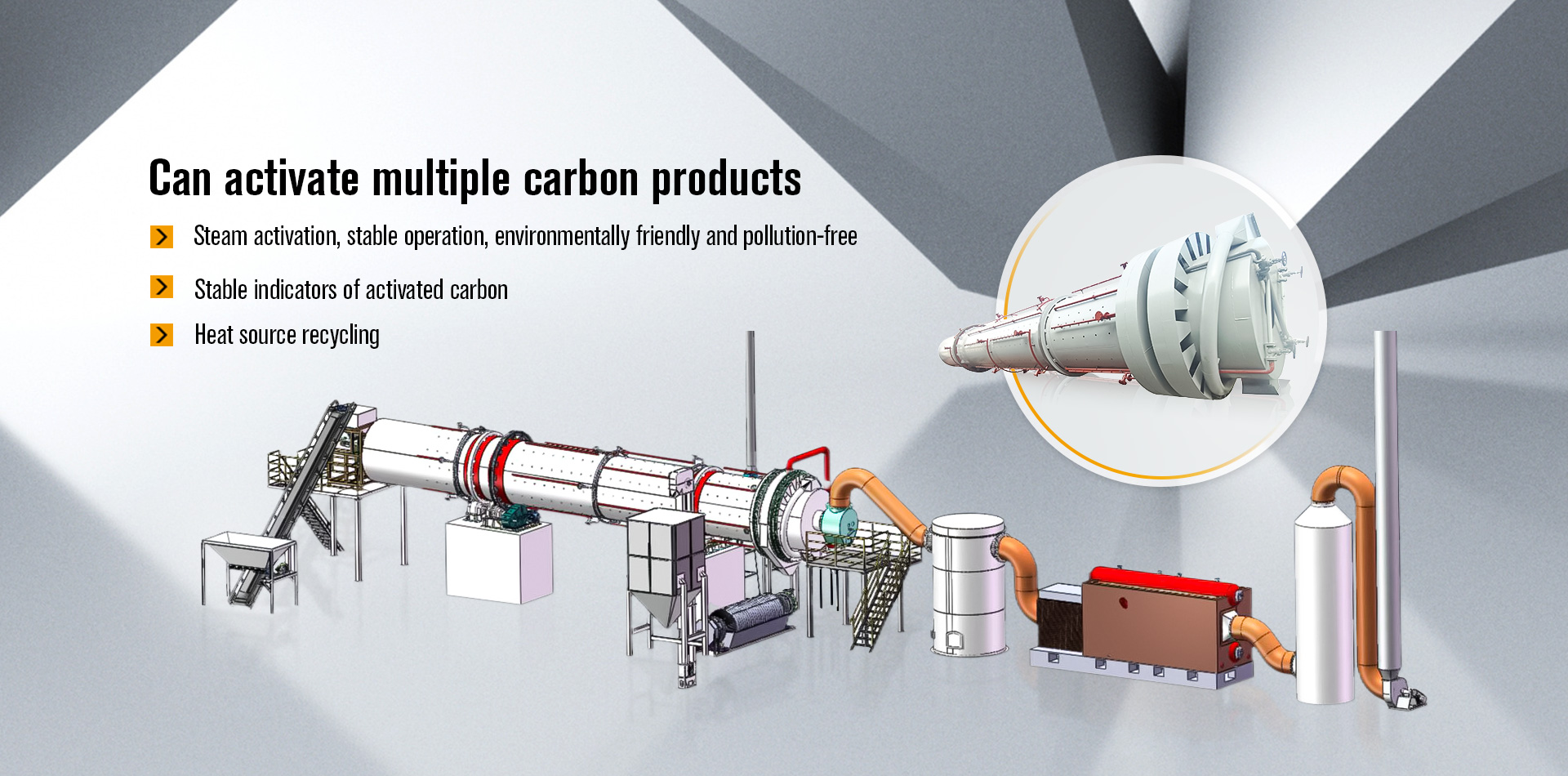

- activated carbon making machinesAdsorption of methylene blue from textile industrial wastewater using activated carbon developed from Rumex abyssinicus plant Shandong Hengyi Kaifeng Machinery Co., Ltd., is professional and experienced in offering activated carbon making machines and activated carbon plants. We mainly adopt activated carbon rotary kiln and physical activation process to realize carbon activation. Physical activation usually refers to gas activation. It uses water vapor, carbon dioxide, or air as the activating gas, and selectively oxidizes the carbonized material at a high temperature of 800-1000 °C so that the original pores in the material are further enlarged, new pores are generated, and the tar and other substances are removed.

2023 04/25

- Coconut Activated Carbon MarketWith the development of carbonation technology, a large number of coconut shells can be converted into biomass charcoal. What`s more, coconut shell charcoal can be reprocessed into activated carbon, and the activated carbon is widely used in smelting, chemical fields. A research study conducted by MarketsandResearch.biz with the title Coconut Activated Carbon Market 2023 contains a clear plan of the announced data as pie diagrams, follows, the line follows, and various updates which isolate the genuine data into sensibly clear longings. The report provides a complete overview of the global Coconut Activated Carbon market with detailed insights on key aspects including the current market situation, potential size, volume, and dynamics of the market. The report offers substantial information about market size and estimation, market share, global growth, and product significance. It consists of a thorough analysis of the market which will help clients acquire market knowledge and use it for business purposes.

2023 04/06

- Global Activated Carbon Mobile Filters MarketGlobal Activated Carbon Mobile Filters Market [2023-2028] | Report Highlight Industry Potential to Achieve Revenue of USD 218.4 Million The Global Activated Carbon Mobile Filters Market Size Reached USD 122 Million in 2021-2022. It is Expected to Grow at a CAGR of 10.2% till 2028. The Global Activated Carbon Mobile Filters Market is to Reach the Value of USD 218.4 Million by the End of 2028. Top Regions Covered in this Report. [North America, Europe, Asia-Pacific, South America, Middle East and Africa, And the Rest of the World] 91 Pages Report Shandong Hengyi Kaifeng Machinery Co., Ltd., is the professional factory to make Biochar Production Equipment in China. The biochar production equipment can use various biomass wastes as raw materials, such as straw, rice husk, wood chips, sawdust, palm shell, coconut shell,etc. And the final products are biomass charcoal, tar and wood vinegar. And they all have wide application.

2023 03/29

- Wood Carbonizing MachineWood Carbonizing Machine Carbonization Furnace For Charcoal wood chips/blocks carbonizing and gasification furnace wood chips carbonizing machine blocks carbonizing machine coconut shell carbonizing machine palm shell carbonizing machine biomass carbonizing machine PROCESS AND PRICIPLE: Such stove feeding from top, burning from bottom, use raw material self-burning heating for carbonizing, max control the air go in quantity, auto feeding and output. it's a less-oxygen low temperature carbonizing and gasification stove, the charcoal is very suitable for next procedure(activation), a type of comprehensive utilization equipment for biomass material.

2023 03/02

- Coconut Shell Charcoal Plant Machinery ManufacturersCoconut Shell Charcoal Plant Machinery Manufacturers in china Our machinery is manufactured with the latest technology with durable, reliable, and quality-tested products under the supervision of our experts. activated carbon making machine activated carbon regenerate machine activated carbon cooling machine activated carbon drying machine activated carbon packaging machine activated carbon transport machine activated carbon lift machine We manufacture completely involuntary coconut shell charcoal making machines for all coconut operations such as activated carbon, coconut oil, charcoal from coconut can be prepared under the help of heat produces from the charcoal machine. With enhanced industrial knowledge, Our Engineers have been able to provide one of the high quality best charcoal making machine manufacturer. We also give needed features such as long-lasting services, easy installation, proper timing for delivery to our customers. We provide all in one solution for all your necessary requirements which includes coconut shell plant machinery, any time quality service for machine and supports customer to solve their queries 24*7.

2023 02/20

- Activated Carbon Plant Machinery ManufacturersActivated Carbon Plant Machinery Manufacturers in china Our machinery is manufactured with the latest technology, and we provide one-stop solutions for all your needs. With more than 10+ years of experience and knowledge in manufacturing industry, we are dedicated in providing the best activated carbon manufacturing machinery in china with exceptional features. With us you can also grab the technical experts advice for machinery installation and production of activated carbon. Our machinery reduces cost and risk and enables manufacturing. An innovation enabled by our Engineers result in affordable price, increased production & consumes less energy. Our technicians are ready for a live demo show and guide you with the specific working conditions in case of any difficulties. Boost your production of activated carbon through our high speed activated carbon manufacturing machine. We are Pollution-free activated carbon making machine suppliers in India as per the guidelines. Our team of professionals will help our clients to perform the machine operations systematically. Customer satisfaction is our main priority; we provide 24*7 customer service in your workspace.

2023 02/09

- Coconut Shell Charcoal Making MachineCoconut Shell Charcoal Making Machine Description of coconut shell charcoal making process 1. First by the forklift smash particles less than 50 mm of coconut shell silo belt conveyor to quantitative feeder, the feeder quantitative uniform into carbonization machine; 2. Carbonization process in the dissemination of the combustible gas by a cyclone dust remover, spray dust collector, enters into the condensation analyzer system, precipitated tar, wood vinegar through a draught fan introducing carbon machine to heat as carbonization pyrolysis heat. 3. The high-temperature exhaust gas after combustion as the heat source for possible drying heating system, then coconut shell becomes charcoal. With the development of carbonation technology, a large number of coconut shells can be converted into biomass charcoal. What`s more, coconut shell charcoal can be reprocessed into activated carbon, and the activated carbon is widely used in smelting, chemical fields.

2023 01/25

- Work flow of carbonization furnaceWork flow of carbonization furnace The charcoal machine mainly consists of the gasifier, the carbonization stove, the cooling system, auto-feeding conveyor and discharging conveyor, dust-removal device, gas cleaner system and other equipment. And the whole working process is as follows: 1. Gasifier equipment can produce gas fuel by heating the raw material. 2. carbonization furnace can be used by the carbonization stove to heat the raw materials. 3. Dust-removal device will remove the dust in the gas by the recycling water. 4. Gas cleaner will make gas clean, you can use the gas to heat, which will not pollute the environment. 5. Cooling and discharging conveyor will cool the charcoal when discharging.

2023 01/05

Email to this supplier